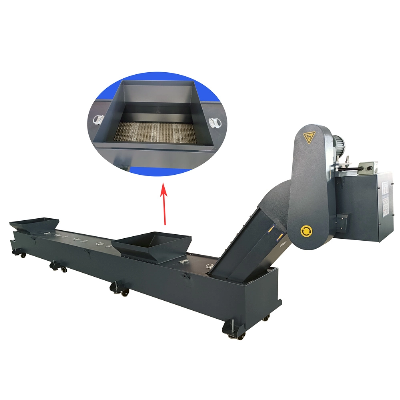

Product characteristics and uses1. Small volume and high efficiency. It

is the most suitable model

for CNC, NC and industrial machinery.2.

The variety of chain plate widths provides excellent matching

flexibility and efficient

applications3.Integrated chain plate combination, high strength, accurate coordination, stable and quiet action.4.Tight convex point design can effectively prevent chip attachment and increase the

chip removal ability.5.

Torque limit setting, effectively reduce the damage caused by improper operation.6.

Excellent automation tool for chip

conveyorTechnical ParametersSpecificationoptionsReduce Speed

Motor1/4Hp(0.2KW)1/165/220/380vCE Specification DeviceSimple CE

device of exitPitch of ChainR2050P=31.75mmFullcover CE device of

exitHined beit Width175,150-600 (there is one king of

specification every 50mm)Manual Conteol Devicelligent

TechnolStandard emergent stopCEspec standerd emergent stopChips

holderOne Pieces for every six pitchVarious far lerminal control

boxesConveyor speed1.2-1.4M/min(50/60Hz)Various romote contriller

cable linesSafety DevieHTL-350-2Torque linit deviceAngle of

Conveyor60°revent chips roll up deviceMachine PhotosChip conveyor

type1, Chain chip conveyor;Product Features and UsesI, Small in

size and high in efficiency, it is the most suitable matching model

for CNC, NC, and industrial machinery.II, The diversified width of

the chain plate provides excellent matching elasticity and

effective applications.III, The integrated chain sheet combination

has high strength, precise coordination, and stable and quiet

movements.IV, Tight convex design can effectively prevent debris

from adhering and increase the ability to remove debris.V, Torque

limit setting effectively reduces damage caused by improper

operation.Scope of application: Suitable for lathe, gantry, CNC and

other machine tools.Main function: Suitable for removing coil

scraps, metal iron scraps, cast iron scraps, aluminum iron scraps,

and non-metals.2, Scraper chip conveyor;Product Features and UsesI,

For iron filings produced by processing metal materials in powder

or granular form, with a length less than 100MM,II, Separate the

fine particles from the oil or cutting fluid, and the coarse

particles are discharged by a chain belt magnetic machine,III, The

powder is separated and discharged by a magnetic clutch, and there

is also a magnetic frame inside the oil tank, so thatIV, Ensure the

purity of the cutting iron liquid.V, If the coolant is oil, coupled

with an oil cooler, it can ensure the oil temperature during

processing, which is even moreVI, Ensure the machining accuracy of

the machined parts.VII, Small in size and high in efficiency, it is

the most suitable model for removing copper, aluminum, cast iron

and other debris.VIIIThe width of the scraper is diverse, providing

excellent elasticity and effective application.IX, The sturdy

scraping combination has high strength, precise coordination, and

stable and quiet movements.X, Torque limit setting effectively

reduces damage caused by improper operation.XI, Suitable for

casting iron chips, aluminum chips, copper chips, and powdered

waste chips.XII, Not suitable for rolled wire and long, blocky iron

filings. 3, Magnetic Chip Conveyor;

4, Screw Chip

Conveyor.ApplicationProject CaseOur certificateExhibition

PackageCooperaton partnerAbout us Guangdong Quanguan

Intelligent Technology Co., LTD., located in Humen Town, Dongguan

City, was established in January 2017 with a registered capital of

100 million yuan (formerly known as Dongguan Dry Guan Machine Tool

Accessories Co., LTD., founded in 2005). The company has long been

committed to the research and development, production and sales of

CNC machine tool accessories, including chip removal machine, oil

chiller, water cooler, heat exchanger, cabinet air conditioner and

other products.Our Services1. Reply the email and take action in 24

hours.2. 100% Quality inspection before the shipment.3. Engineer

overseas is available. Introduce our engineer come to customer's

factory working.4. Auxiliary machines for complete line.5.

Customized design as requirements.FAQQ1: Are you a manufacturer or

trading company?A1: We are a professional manufacturer

specialized industrial refrigeration equipment for over 16

years, We have our own designers, and the

machines have been patented.Q2. How to get an accurate

quotation?A2: The customer should provide the related technical

requirements, drawings, packing requirements, etc.Q3: How long is

your delivery time?A3: Generally, it will take 30 working days

after receiving your down payment. The exact delivery time

depends on the items and the quantity of your order. Sometimes

we have existing products in stock.Q4. How does your factory do

regarding quality control?A4: QUANG has been regard quality as

the priority. We always attach great importance to quality

controlling from the very beginning to the very end, so our

Related products about Roller Chain Screw Magnetic Scraper CNC Conveyor Hinged Chip Conveyor for Metal

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup