Sand castingsWhen you need a metal part that's both accurate and

inexpensive, metal casting is an ideal choice. Whatever type of

casting you need, our staff at RH Metal and engineers at our

casting foundry, will analyze your particular requirements and

recommend the most effective and economical casting method, metal

alloy.We specialize in a wide range of custom metal cast parts as

mentioned above and include:Electric Motor HousingsGear BoxesPump

Housings and PartsValve Bodies and PartsFire Sprinkler Frames and

Fire Sprinkler PartsArchitectural parts and elementsMarine parts

and Sporting equipment partsAnd many other industrial and

commercial cast metal partsContact RH Metal to schedule a

consultation. We offer technical and design assistance to help

ensure that your finished parts are as strong as they can possibly

be. RH Metal specializes in several different casting methods;

Additional Casting ServicesIn addition to the casting operation, we

also offer value-added services such as full or

partial machining components and surface conditioning such

as:Painting (dip or spray)Plating (all types such as Chrome,

nickel, flash copper, brushed finish, oil bronze finish,

etc.)Powder coatingAnodizingWe also offer semi or fully assembled

parts or sub-assemblies.RH Metal Foundries Quality

AssuranceOur foundries have established an effective quality

assurance system and ensure parts are produced accurately and in

compliance with ASTM &GB standards. Our plants use

hand-held measuring devices, spectrometers and other quality or

mechanical measuring equipment to inspect all the metal castings

and parts RH Metal sells to all our world customers.GI

HT 100MaterialDIN GG10, JIS

FC100production processSand casting,resin sand casting,shell

mould casting,die casting,gravity casting,investment casting,laser

cutting,gear milling,punching,weldingApplication scope of GI

HT100Apply to light loading or parts as condition in no specific

requirements of friction and wearing. Such as protection

shield,cover,lacquer tray,hand wheel,bracket,base plate,weight

dropper , small size handle or etc.GI HT 150MaterialDIN

GG-15, UNS F11401, AISI 20, JIS

FC150production processSand casting,resin sand casting,shell

mould casting,die casting,gravity casting,investment casting,laser

cutting,gear milling,punching,weldingApplication scope of GI

HT150working scope,medium loading work castings,like engine

base,bracket/brace,G/Box housing,cutter holder,lathe bed,bearing

seat,operating platform, belt roller,end cover,pump n valve

body,tube line,freewheel,motor pedestal or etc.GI HT

200Material : DIN GG-20, UNS F11201, AISI

30, JIS FC200production process:Sand casting,resin

sand casting,shell mould casting,die casting,gravity

casting,investment casting,laser cutting,gear

milling,punching,weldingApplication scope of GI HT200to load

relative heavy stress and support some rated gas tightness or

corrosion attack parts which are comparatively important.

Such as gas cylinder,gear,Engine base,flywheel,lathe

body,pneumatic sleeve,piston,gearbox,brake wheel,coupling

disk,medium pressure valve body and etc.GI HT 250Material :

DIN GG-25, UNS F12401, AISI

35, JIS FC250production process:Sand casting,resin

sand casting,shell mould casting,die casting,gravity

casting,investment casting,laser cutting,gear

milling,punching,weldingApplication scope of GI HT250to load

relative heavy stress and support some rated gas tightness or

corrosion attack parts which are comparatively important.

Such as gas cylinder,gear,Engine base,flywheel,lathe

body,pneumatic sleeve,piston,gearbox,brake wheel,coupling

disk,medium pressure valve body and etc.GI HT300Material :DIN

GG-30, UNS F13101, AISI 45, JIS

FC300production process:Sand casting,resin sand casting,shell

mould casting,die casting,gravity casting,investment casting,laser

cutting,gear milling,punching,weldingApplication Application of GI

HT300,heavy duty load,important component castings needs abrasion

proof and high air tightness. such like heavy duty lathe,shearing

machine,punching machine,bed of self acting lathe,engine

base,machine frame,high pressure hydraulic piece,piston ring,heavy

duty load gear wheel,cam,liner/bushing, crankshaft of high rating

generator, pneumatic cylinder and accessories or

etc.DIQT400Material :DIN GGG-40, UNS

F32800, AISI 60-40-18, JIS

FCD400production process:Sand casting,resin sand casting,shell

mould casting,die casting,gravity casting,investment casting,laser

cutting,gear milling,punching,weldingApplication:Ductile iron

application QT400, traction frame of automobile and

tractor,nave/hub/drum,clutch and reducer body,plough share,plough

leg,atmospheric pressure valve and its accessories, in/out gas pipe

of low and high gas feeding pressure cylinder, railway pad, g/b

housing, fly wheel or lathe parts.DIQT450 Material : UNS

F33100, AISI 65-45-12, JIS

FCD450production process:Sand casting,resin sand casting,shell

mould casting,die casting,gravity casting,investment casting,laser

c

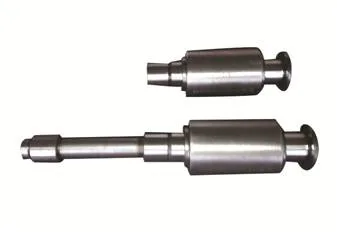

Related products about Floating Axle Flexible Shaft Rigid Shaft

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup