Company Profile Hangzhou Xinfeng Magnetic Materials Co.,

Ltd.Hangzhou Xinfeng Magnetic Materials Co., Ltd., was founded in

2000 which is located in Hangzhou city, Zhejiang Province, China.

It is a new high-tech enterprise specialized in the research,

production, application and development of permanent magnet

materials.Our main business are: NdFeB magnets; SmCo

magnets; AlNiCo magnets; Ceramic (Ferrite

magnets); Rubber magnets and Magnetic Assembly. Our production

technology is in the domestic leading and international advanced

level. More than 20 extraordinary years make us become one of the

enterprises with the largest production scale and the most complete

permanent magnet products in the permanent magnet industry.Xinfeng

Magnet covers an area of 30,000 square meters, with more than 300

staffs and 5000 tons annual capacity. The company has the most

comprehensive testing laboratory and sophisticated testing

equipment to ensure the quality of the products. We have passed

ISO9001:2001 and TS16949:2009 quality management system

certification. Our strong R&D team and excellent R&D

capability enable us obtain a number of national patents.Our

products are widely used in Motor, Electroacoustic, Automotive,

Instrument, Communication, Household Applications, Medical Device,

Wind Power, Aerospace and other high-tech and future Energy Fields.

Our main markets are North America, South America, Japan and South

Korea, Southeast Asia, India and other countries and regions.

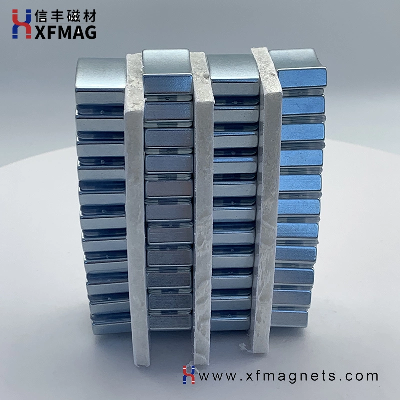

Detailed PhotosNdFeb has the best performance among the rare-earth

permanent magnets. It is the rare earth permanent magnet with the

strongest magnetic property at present. It has an extreme high BH

max and good Hcj, and greatly machinability. It is the most widely

used permanent magnet material in the industrial field and known as

the "Magnet King".As NdFeB is easily oxidized or corroded, it can

be plated or coated according to the requirements of the working

environment of the product. The coating could be nickel,

nickel-copper-nickel, zinc, tin, chromium, black epoxy,

phosphorization, not plating, etc. All coatings meet the

requirements of RoHS.NdFeb is the alloy magnet

of Neodymium (Nd), Iron (Fe), Boron (B) and some other

microelements, produce through the Powder Metallurgy

technology. China owns abundant rare earth resources and

supplies the world 70% rare earth magnets.At present, the

performance of our products has reached the first-class level of

the world. Our products have been widely used in aerospace,

medical, electronic equipment, automotive equipment, motors,

generators, nuclear magnetic resonance, magnetic levitation,

magnetic separator, electro-acoustic fields, etc. Product

Parameters MAGNETIC PROPERTY PARAMETERS OF SINTERED NDFEB MAGNETGradeBrHcbHcj( BH )maxTw:ºC mT(kGs)kA/m(kOe)kA/m(kOe)kJ/m3(MGOe) N351170-1220(11.7-12.2)≥868(10.9)≥955(12)263-287(33-36)80ºCN381220-1250(12.2-12.5)≥ 899(11.3)≥955(12)287-310(36-39)80ºCN401250-1280(12.5-12.8)≥907(11.4)≥ 955(12)302-326(38-41)80ºCN421280-1320(12.8-13.2)≥915(11.5)≥955(12)318-342(41-43)80 ºCN451320-1380(13.2-13.8)≥923(11.6)≥955(12)342-366(43-46)80 ºCN481380-1420(13.8-14.2)≥923(11.6)≥ 955(12)366-390(46-49)80 ºCN501400-1450(14.0-14.5)≥796(10.0)≥876(11)374-406(47-51)80ºCN521430-1480(14.3-14.8)≥796(10.0)≥876(11)390-422(49-53)80 ºCN541450-1510(14.5-15.1)≥836(10.5)≥876(11)406-438(51-55)80 ºC33M1130-1170(11.3-11.7)≥836(10.5)≥1114(14)247-263(31-33)100 ºC35M1170-1220(11.7-12.2)≥868(10.9)≥1114(14)263-287(33-36)100 ºC38M1220-1250(12.2-12.5)≥899(11.3)≥1114(14)287-310(36-39)100 ºC40M1250-1280(12.5-12.8)≥ 923(11.6)≥1114(14)302-326(38-41)100 ºC42M1280-1320(12.8-13.2)≥955(12.0)≥1114(14)318-342(40-43)100 ºC45M1320-1380(13.2-13.8)≥ 995(12.5)≥1114(14)342-366(43-46)100 ºC48M1360-1430(13.6-14.3)≥ 1027(12.9)≥1114(14)366-390(46-49)100 ºC50M1400-1450(14.0-14.5)≥1033(13.0)≥1114(14)382-406(48-51)100 ºC52M1420-1480(14.2-14.8)≥1059(13.3)≥1114(14)390-422(49-53)100 ºC35H1170-1220(11.7-12.2)≥868(10.9)≥1353(17)263-287(33-36)120 ºC38H1220-1250(12.2-12.5)≥ 899(11.3)≥1353(17)287-310(36-39)120 ºC40H1250-1280(12.5-12.8)≥923(11.6)≥1353(17)302-326(38-41)120 ºC42H1280-1320(12.8-13.2)≥955(12.0)≥1353(17)318-342(40-43)120 ºC45H1320-1360(13.2-13.6)≥963(12.1)≥1353(17)326-358(43-46)120 ºC48H1370-1430(13.7-14.3)≥995(12.5)≥1353(17)366-390(46-49)120 ºC50H1400-1450(14.0-14.5)≥1027(12.9)≥1274(16)374-406(47-51)120 ºC35SH1170-1220(11.7-12.2)≥876(11.0)≥1592(20)263-287(33-36)150 ºC38SH1220-1250(12.2-12.5)≥907(11.4)≥1592(20)287-310(36-39)150 ºC40SH1250-1280(12.5-12.8)≥939(11.8)≥1592(20)302-326(38-41)150 ºC42SH1280-1320(12.8-13.2)≥987(12.4)≥1592(20)318-342(40-43)150 ºC45SH1320-1380(13.2-13.8)≥1003(12.6)≥1592(20)342-366(43-46)150 ºC48SH1360-1400(13.6-14.0)≥1034(13)≥1592(20)366-390(46-49)150 ºC28UH1020-1080(10.2-10.8)≥764(9.6)≥1990(25)207-231(26-29)180 ºC30UH1080-1130(10.8-11.3)≥812(10.2)≥1990(25)223-247(28-31)180 ºC33UH1130-1170(11.3-11.7)≥852(10.7)≥1990(25)247-271(31-34)180 ºC35UH1180-1220(11.8-12.2)≥86

Related products about N42 Neodymium NdFeB Magnets Arc Neodymium Block Magnet Magnetic Product

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup