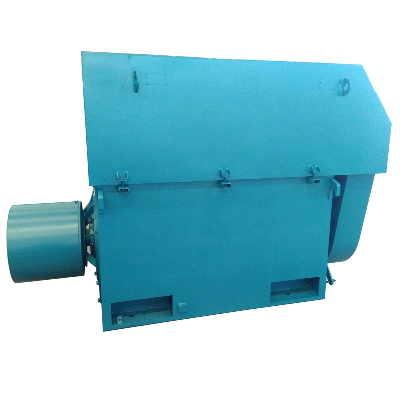

The wound rotor motor is a slip ring three-phase asynchronous

motor. The power rating, installation dimensions and electrical

performance of this type of motor comply with the relevant IEC

standards. The basic installation method of the motor is the

horizontal bottom angle (IMB3), the working system is the

continuous working system (S1), and the wound rotor is made of

Class F insulation material.The winding rotor motor has two types

of bearings: rolling bearing and sliding bearing, depending on the

motor power and speed. The rated frequency of the motor's power

supply is 50Hz, the rated voltage is 6000V/10000V, and the basic

type of protection is IP54. The motor slip ring housing can be

protected to IP22 or IP23. Other voltage, frequency and degree of

protection motors are also available upon request.Wound rotor

motors can be used to drive a variety of different machinery, such

as compressors, pumps, crushers, cutting machine tools,

transportation machinery and other mechanical equipment, in mining,

machinery industry, petrochemical industry, power plants and other

industrial and mining enterprises. Used as the prime mover. The

motor used to drive the blower, coal mill, rolling mill and winch

should indicate the purpose and technical requirements when

ordering, and adopt special design to ensure reliable operation.*

Technical parameter:Power range:100kw-10000kwFrame

Size:355-1000mmRated Voltage: 380v~760v, 2.4 kv, 3 Kv 3.3 KV,

4160 V, 6 Kv 6.6 KV, 10 KV, 11 KVPole: 4, 6, 8, 10, 12Speed:

1500rpm, 1000rpm, 750rpm, 600rpm, 500 rpm --for 50Hz power

supply

1800rpm, 1200rpm, 900rom, 720rpm, 600 rpm -- for 60Hz power

supplyProtection Class: IP23, IP44, IP54, IP55Cooling type: IC01,

IC611, C616, IC81W* Operation conditions:Altitude: =<

1000m;Ambient temperature: -15- 40ºCInput power frequency:

50Hz±l%;Voltage: ±5% rated voltage;Duty: S1(

continuous). Comparison of different series

High Voltage motorsNo.Squirrel-cage motorY JSYKKYKSY2, Y3Slip ring

motorYR JR JR2YRKKYRKSYR2, YR31StructureBox-type construction, made

up of steel plates welded with each otherCompact struction2Cooling

methodIC01 or (IC11, IC21, IC31)IC611 or IC616IC81WIC4113Natural

ventilation, with top mounted protection coverWith top mounted

air-air coolerWith top mounted air-water cooler 4Protection

typeIP23IP44 or IP54IP44 or IP54IP545InsulationF6Mounting

arrangementIMB37Voltage available380 v, 2400 v, 3kv,

3.3kv; 4160 v, 5500V 6kv,

6.6kv; 10kv, 11kv8Frequency

available50Hz , 60Hz * Advantages:High

efficiency,Energy-saving,Low Noise,Low vibration,High start

torque,Low start current,Light weight and reliable performance.Easy

for installation and maintenance.The company insists on providing

high-quality motor products and services to users, and has won high

praise from many domestic and foreign customers. The company will

receive many foreign merchants to visit our factory every year, and

establish a good cooperative relationship through on-site

inspection of our factory. Our company always welcomes customers to

visit our factory.The company has large-scale laboratory,

intelligent CNC winding machine, CNC rising machine, automatic

wrapping machine, VPI high pressure vacuum immersion system,

large-scale dipping paint drying furnace, 60 tons test platform,

large vertical car, milling machine, grinding machine, Each type of

dynamic balancing machine, double-feedback test and detection

system with 6MW (12MW) motor and other motor production

professional equipment more than 500 sets, sound mechanical

equipment processing capacity, to lay a good foundation for

customers to improve good quality motor products.Our company's

motor manufacturing factory adheres to the concept of green,

efficient and energy-saving production service, pays attention to

the harmonious development of internal and external environment,

builds environmentally friendly motor manufacturing enterprises,

strictly implements motor standard process, and selects

high-quality energy-saving materials to ensure the quality of motor

products. /* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Voltage Slip Ring 3-Phase Asynchronous AC Electric Induction Motor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup