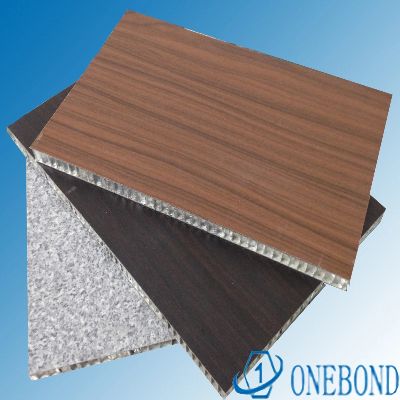

01. About honeycomb panelAluminum honeycomb panel are mainly used

for the decoration of ship and building. These products are made of

high-quality imported raw materials, and processed with high

precision. Its surface employs the advanced technique of

fluorocarbon lacquer pre-roll coating, which can keep the color

unchanged for 15 years. The company has adopted t and bi-component

modified epoxy resins and has used fully automatic manufacturing

facilities of honeycomb panels to compound product under

pressurized high temperature through completely-closed and

dust-free operation, which make the honeycomb panels sticker, more

bending resistant, straighter, and thus steadier and more reliable

in quality. All kinds of alloyed honeycomb panel, such as curl

panels, folded panels and trapezoidal panels, can be fabricated

according to the requirements of architectural design. The alloyed

panels with non-planar surfaces, such as circular arc, L type and U

type, are produced by one-step forming with dies. It is a kind of

organic and environmentally protective decorating material with

high quality, light, high strength and magnificent appearance.02.

Product detail03. Product SpecificationProduct Name

Aluminum Honeycomb panelApplication Marine

decoration, curtain wall, ceiling, partition, exterior decoration,

interior decoration etc.Certification Lloyd's Register,

ISO9001:2000, BV, SGS.Regular Totall Thickness 6mm, 8mm,

10mm, 15mm, 20mm, 25mm, 30mm, 50mm, 100mm, 200mm etc.Regular Top &

Bottom Aluminum sheet 0.5-1.5mmStandard

sepcification Cell size: 8.47mm, aluminum foil thickness:

0.05mm.SizeStandard size: 1220*2440mm, normal max size:

1500*6000mm.Note: Price is adjusted according to different size, we

can produce the size which is exceed normal max size.Raw

Material3003, 5052 etc.Surface treatment PE, PVDF,

Anodized etc.Color typeSolid colors, Metallic colors, Wood grain,

Marble and customized color etc.Service Range- Provide professional

design and suggestion.- Manufacture products in accordance with

customer drawings. -Arrange shipment04. Technical

ParameterThickness Unit6 mm10 mm15 mm 20 mm 25 mm Cover

sheet thickness, front [mm]1.0Cover sheet thickness,

rear [mm]0.50.51.01.01.0Weight [kg/m²]4.75.06.77.07.3 Technical

properties Section

modulusW[cm³/m]2.64.6141924RigidityE@J[kNcm²/m]7.10021.90075.500138.900221.600Alloy

/ Temper of Aluminium Layers Peraluman alloy (AIMg), H42

acc. EN 573-3Modulus of Elasticity E[N/mm²]70.000Tensile

Strength of Aluminium R m[N/mm²] ≥ 1250.2 % Proof

Stress R p0,2[N/mm²] ≥ 80Elongation A 50[%] ≥

5Linear Thermal Expansion α 2.4 mm/m at 100ºC

temperature

difference Core Aluminium

foils from AIMn alloys (EN AW-3003) Bare comprehensive

strength [N/mm²]> 2.5 Weight [kg/m³]>

50 Surface

Lacquering Coil

Coating Fluorocarbon based (e.g. PVDF) Gloss (initial

value) [%]25-40 Pencil

Hardness HB-F Acoustical

Properties Sound Absorption Factorα

s 0.05 Airborne sound insulation index (acc. to ISO

717-1, ISO 140-3) R

w[dB]2121222325 Thermal

Properties Termal conductivity

(regarding total thickness, incl. cover sheets)

λ[W/mK]0.951.351.782.252.70 Thermal

resistanceR[m²K/W]0.00630.00740.00840.00890.0093 Temperature

Resistance [ºC]-40 to +80 05. Main featuresA. Light

specific gravity, high rigidity, steady, structure and high

wind-resistance performance.Curtain wall aluminum honeycomb panels

have been extensively applied to extemal wall decoration of

high-rises. Honeycomb panels of the same rigidity have a weight

that is only 1/5 of aluminum panels and 1/10 iron panels, whose

total thickness being 15mm, panels 1.0mm thick and bottom panel

0.8mm thick have a weight of only 6 kgs per square meter.The

interconnected honeycomb cores are like numerous I bar with

interface layers distributed within the whole panel, thus resisting

shearing and bending and large pressure. Its wind-resistance

performance has greatly exceeded that of aluminum composite panel

and aluminum solid panel, so that even large- sized honeycomb

panels can reach extremely high straightness, aluminum honeycomb

panels can reach ghe higest intebsity and bending resistance with

the lightest weight, which is an incomparable compared to other

materials, thus making it currently the preferred light weight

material in the building industry.B. Excellent performance in sound

insulation, heat insulation, reproofing and quakeproof. Since the

honeycomb cores in aluminum honeycomb panels are divided into many

enclosed cells, which stops air flows and blocks heat and sound

waves with 20-30DB, noise reduction for sources from 100HZ to

3200HZ and a heat conduction coefficient of 0.104-0.130W/M.k,

aluminum honeycomb panels is an ideal energy-saving material with

an energy absorption capability of 150~3500KJ/M. For example, when

it is raining, rains dropping on the aluminum solid panels or

aluminum composite panels will make a loud noise, but if replaced

them with honeycomb panels, no such

Related products about Aluminum Honeycomb Panel

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup