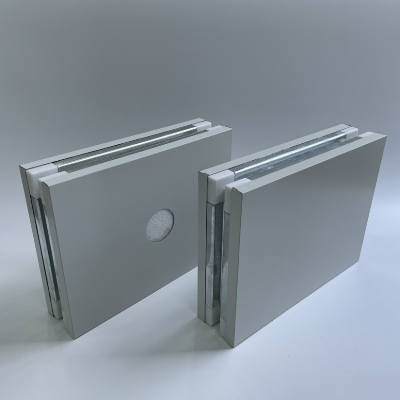

The hand made PU panel use high-quality color coated steel plate as

the panel and EPS panel as the inner core layer,galvanized frame is

used all around specification :Width(MM)950/1150Thickness

(MM)50/75/100/150/200Length Customized according to project

requirements and conditions of transportColor According to the

engineering requirements Variety H plate(plate,pressure

type),tongue and groove panel,corrugated sandwich

panel Self-weight10.0-13.6KG/M2Thermal

conductivity 0.034-0.037w/m.kOxygen Index(oi)34.0(Fire Product

Quality Supervision,Inspection Station)Sound insulation

performance 19dB(A)(75MM) CorePolystyrene foam panel

should be consistent with the provision of GB10801,the bulk density

of not less than 12KG/M3,the thermal conductivity of not more than

0.041W/(mk),flame resistance(ZR),the oxygen index of not less than

30% binderThe bond strength should be greater than

0.1MpaStripping performance Stripping experiments,the

polystyrene foam particles bonded on the surface material should be

distributed evenly .Each stripped surface bonding area should be

not less than 85%Advantages:1.The density coefficient is small, has

good impact resistance, even in the face of external strong impact,

can also be well restored before the shape size.2. It has an

independent structure, even if a small area is damaged, it

will not affect the whole wall.3. The water absorption rate of EPS

board is very low, and the permeability prevention ability is

strong, which can effectively avoid the phenomenon of moisture and

mildew on the wall surface and the wall problems such as falling

off.4. basically will not be affected by temperature. It does not

melt in the heat like ordinary foam; And it won't crack because of

the low temperature.5. it is a kind of recyclable material,

can be recycled and reused; Therefore.6. The energy consumption in

the whole life cycle is the lowest among all types of foam

boards.Features:1.Simple splicing mode: Insert type or middle type

connection mode, convenient installation, effectively reduce the

installation cost.2.Short installation cycle: No secondary

processing on site, can keep the surrounding environment clean,

does not affect the normal process of other processes, can greatly

shorten the installation cycle of the panel.3.Scratch protection:

During the production , polyethylene self-adhesive protective

film can be pasted on the surface to avoid scratches or wear on the

surface coating of steel plate during transportation and

installation.Factory workshop : Factory facilities :

Factory shipment:FOOD AND PHARMACEUTICALNEW

ENERGY/SEMICONDUCTOROVERSEAS REFERENCE FAQQ:1. Why is

the price so low? You are ordering

directly from the factory.Q:2. Where is your factory located? How

can I visit there? Our factory is

located in Suzhou City, Jiangsu Province, China,which is near

Shanghai. All our clients, from home or

abroad, are warmly welcomed to visit us.Q:3. Can you

make the products with my design? Yes.

customization is welcome .Q: 4.How many years have we

created? A: Our company was found in 2005,we

have more than 10 years experience in cleanroom sandwich

panel , door and

windows , we know how to properly handle each step of

products Q: 5.Can I get a sample?A: Yes, the

samples are free for you,and you need to afford the fee for

samples shipping.

It usually takes 3-5days. Q: 6.How can my order produced by my

brand?A: If your order quantity reaches two

containers, We could produce OEM production

freely after you offer LOGO design. In case

that your order quantity cannot reach

two containers, you need to pay additional 800 for this OEM

production. Q: 7.What's your delivery

time?A: Except our legal holiday, it will take 2

weeks for us to finish all your orders' production. Q: 8.Is

there a minimum order requirement?A: Due to the

high machine setup cost and shipping freight, our minimum order

quantity is 500SQM. It is

recommended for you to order a 20"GP to reduce the unit price

and shipping cost.Q: 9.How do you

guarantee your quality?A: Firstly we

have advanced equipment and technology, we alao have

a technical team. Secondly We

cooprated with china famous raw material suppliers to ensure the

high quality of our products. And

last, our products are certified by ISO 9001 and CE Q: 10.What

is your daily output?A: Our daily capacity for handmade

panels is 6000M2 ,machinemade is 4000M2 per day .Add: No316, Tuncun

Eastroad , Tongli Town , Wujiang District , Suzhou

City , Jiangsu Province , china /* January

22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Factory PPGI Steel PU EPS Puf Polyurethane Sandwich Panel for Warehouse

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup